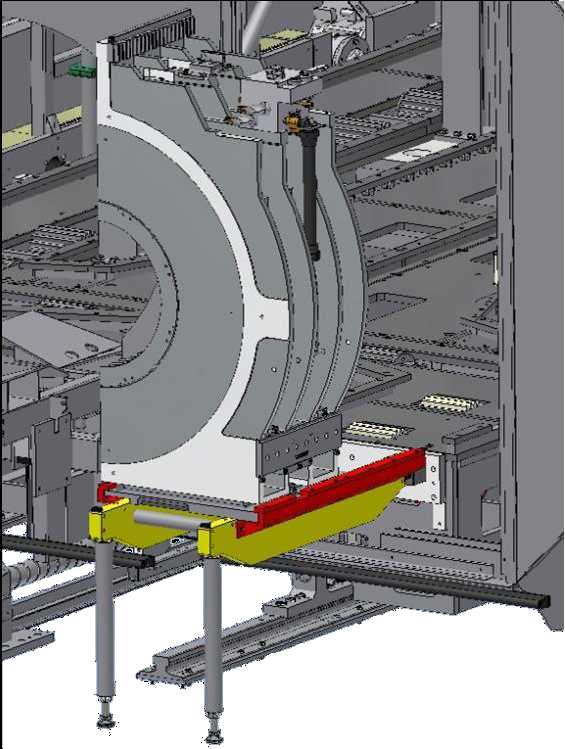

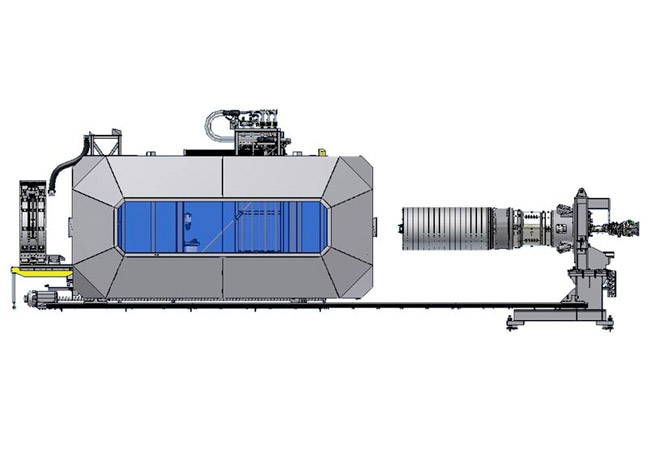

- Mold block change: In order to speed up the change of mold blocks the HD 1200 corrugator is now equipped with swinging doors, this accelerates the access to the inside of the machine. The heating elements of the parking station can be folded aside to have more space to work. At the push of a button the mold blocks are driving on a changing table which will be installed at the exit of the machine. In this way the mold blocks or mold block inserts can be taken very easy outside the machine. Just as easy the new mold blocks are driving back into the machine.